The Customer

Albert Bartlett is one of the top names in potatoes around the world and has recently launched into the Netherlands, France and the USA; all starting from a garden shed in Coatbridge, Lanarkshire.

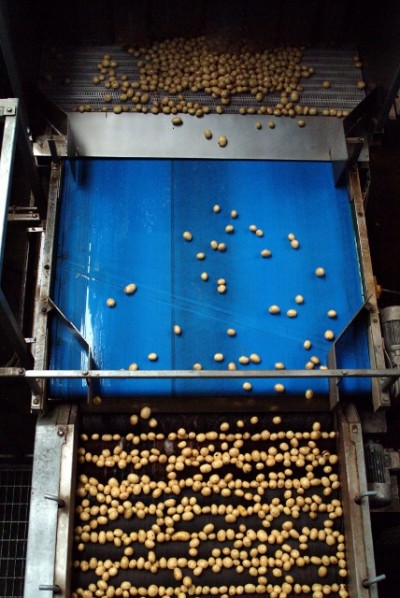

As a top quality vegetable provider, temperature controlled storage is paramount to ensuring that quality and integrity is maintained in these delicate products. To cope with ever-increasing sales of Scottish grown potatoes, new state of the art premises were built by the company in Airdrie in 2002 – Europe’s most advanced washing, grading and packing facility.

ACE Refrigeration – Manufacturer Independence

Established in Glasgow in 1951, our knowledge, breadth of experience and professional indemnity enable us to have a very flexible approach to projects and working partnerships.

Manufacturer independence gave ACE the ability to source from a large pool of top quality worldwide manufacturers allowing us to find the best solution to service Bartlett’s specialist requirements, offering the reliability and energy saving results required by the customer, all within budget.

Indemnified Design

Coupled with our focus on energy efficiency and a indemnified energy saving design, ACE were able to give Bartletts the peace of mind needed on such a large and crucial project which included large scale cold rooms for three large Intake Chills and a large Dispatch Chill.

Energy Efficiency

For some organisations, refrigeration costs can represent more than 50 % of their energy bill, and 20 % of that can be wastage. A modern and energy-efficient refrigeration system will help save you money; we know where energy savings can be made and how to get cost-effective and efficient systems up and running in your business.

Our in-house design team also offer indemnified designs with a focus on energy savings of up to 25% over traditional applications, incorporating temperature monitoring systems. Replacing tired and inefficient equipment can have a major benefit on your bottom line – some of our recent installations have had a payback period of less than 2 years based on the energy savings received; some customers have saved up to 25% off their energy bills.

Also for some of our customers in the UK, we have been able to help secure substantial grant funding for the replacement and renewal of outdated plant.

Service & Maintenance

We have been responsible for the service and maintenance of this site since it was completed in 2002.

Our service & maintenance departments have dedicated teams of fully qualified service & maintenance engineers who work together to achieve a service which is fast, effective and reliable. Our reputation has been built upon our attention to detail and rapid reaction times. To help minimise equipment breakdown and the inevitable disruption to your operation, we offer highly competitive maintenance contracts, individually tailored to meet your needs.

Hydro Coolers

As well as looking after cold rooms for Albert Bartlett, ACE Refrigeration also service and maintain two Hydro Coolers at their Airdrie plant.

Benefits of Hydro Coolers include extending shelf life by precooling vegetables and fruits fast, cools crops up to 15 times faster than air, hydrates certain products, reduces moisture loss and rinses while it cools, offering a more flexible means of cooling vegetables.

Other Clients in the Food Processing Industry

We have carried out major design and installation projects for cold rooms and freezer rooms, ice generators, chilled production facilities and blast chillers and freezers for food processors, bakeries, dairy companies, the fish and seafood industry, the meat business and fruit and vegetable sectors throughout the country.

Customers include:

Go Back

Go Back